- 产品

- 详情

- 推荐

收藏

¥260.00

5-49千克

¥258.00

≥50千克

产品规格

可售数量: 5600千克

合金粉末主要包括Ni-Cr-B-Si系列;Ni-Cr-B-Si-C系列;Ni-Cr-B-Si-C-Mo-Cu系列等,它具有优良的综合性能,耐腐蚀、抗氧化、耐热耐低应力磨粒磨损和粘着磨损等,具有优异的喷焊工艺性。

下而介绍我公司生产的镍基喷焊合金粉末均采用塑料桶和铁桶封装但由于粉末粒度细,易于吸潮,建议用户在使用前采用120℃保温两小时低温烘烤后使用。

| 型号 | 规格(μm) | 特性简述 | 主要用途 | 物理性能 | 应用工艺 |

| 贝达Ni15 | -106/+45 -90/+25 | 熔点低、自熔性好,具有优良耐磨、耐热和抗氧化性能。 | 玻璃模具,塑料模铸铁,机床导轨修复和予保护 | ①HB ②熔点1080℃ ③流动性16s/50g ④松装密度4.7g/cm3 | 氧乙炔一、二步法喷焊工艺。 |

| 贝达Ni25A | -106/+45 -90/+25 -45/+15 | 熔点低、自熔性优良,焊层具有耐磨、耐蚀、抗氧化性能。 | 用于小能多冲击的玻璃模具、平板、滑轨、齿轮面修复和予保护。 | ①HRC22/26 ②熔点1050℃ ③流动性15s/50g ④松装密度4.7g/cm3 | 氧乙炔一、二步法工艺;超音速喷涂。 |

| 贝达Ni25AA | -90/+25 -73/+45 | 熔点极低湿润性好,焊层具有综合性能优。 | 用于玻璃模具止口修复和予保护 | ①HRC21-24 ②熔点850℃/900℃ ③流动性16s/50g ④松装密度4.6g/cm3 | 氧乙炔一、步法喷焊工艺。 |

| 贝达Ni45A | -73/+45 -106/+45 | 熔点低、自熔性优良,焊层具有耐磨、耐热、耐腐蚀、抗氧化性能。 | 用于玻璃模具冲头予保护焊层 | ①HRC42-48 ②熔点1080℃ ③流动性16s/50g ④松装密度4.6g/cm3 | 氧乙炔一、二步法喷焊工艺。 |

| 贝达Ni45Q | -106/+45 -150/+53 -75/+15 | 熔点低、自熔性好,焊层具有耐磨、抗氧化、抗硝腐蚀性好。 | 用于气门进排气阀, 耐泵轴予保护涂层. | ①HRC43-47 ②熔点1070℃ ③流动性16s/50g ④松装密度4.7g/cm3 | 等离子堆焊 氧乙炔喷焊 炉熔工艺 |

| 贝达Ni55AA | -106/+45 -150/+53 | 熔点低、自熔性好,焊层具有良好耐磨、耐热、抗氧化性能。 | 泵柱塞、拔丝轮等机械零件予保护焊层。 | ①HRC50-57 ②熔点1040℃ ③流动性17s/50g ④松装密度4.6g/cm3 | 等离子堆焊 氧乙炔喷焊 |

| 贝达Ni60 | -106/+45 -150/+53 | 熔点低、自熔性好,焊层具有优良耐磨性、耐热、抗氧化性。 | 泵柱塞、风机叶片、拔丝轮、输送辊等予保护焊层。 | ①HRC59-63 ②熔点1040℃ ③流动性16s/50g ④松装密度4.6g/cm3 | 等离子堆焊 氧乙炔喷焊 |

自熔性、润湿性和喷焊性优良,喷焊层具有硬度高、耐蚀、耐磨、耐热特点,难以切削,以湿式磨削为宜。

Category

类 别

Trade- | Chemical | Hardness | Application

| |

Oxy- 氧

乙

炔

焰

喷

焊 | F103 | Cr10 B1.5 Si3 Ni Rem. | HRc 25 | Spray-fusing of cast iron parts, such as die for glass, cylinder, and guide. |

F101 | Cr10 B2.5 Si3 Ni Rem. | HRc 45 | Spray-fusing of parts resistance to wear and corrosion, such as valve, the rotator and piston of pump. | |

F101Fe | Cr10 B2.5 Si3 Fe10 Ni Rem. | HRc 45 | Spray-fusing of corrosion-resistant parts, such as axle and stigma. | |

F102 | Cr16 B4 Si4 Ni Rem. | HRc 60 | Spray-fusing of parts resistance to wear, corrosion and high temperature oxidation, such as die and piston. | |

F102Fe | Cr16 B4 Si4 Fe15 Ni Rem. | HRc 60 | Spray-fusing of corrosion-resistant parts, such as axle and cold die. | |

F105 | F102+50%WC | HRc 60 | Spray-fusing of parts resistance to grain-wear , such as guide plate, scraper and blade of fan. | |

F105Fe | F102Fe+35%WC | HRc 60 | Spray-fusing of parts resistance to grain-wear, such as guide plate, scraper and blade of fan. | |

F108 | F102+80%WC | HRc 60 | Spray-fusing of parts resistance to strong grain-wear and free machining, such as harrow teeth of dredger. | |

F301 | Cr5 B4 Si4 Ni30 Fe Rem. | HRc 45 | Spray-fusing of vulnerable parts of agricultural machinery and mining machinery, such as gear and axletree. | |

Track iron powder 轨铁粉 | Cr5 B1.5 Si3 Ni30 Fe Rem. | HRc 28 | Repair spray-fusing of defects such as scratch and concavity of railroad track. | |

Oxy-acetylene flame spraying

氧 乙 炔 焰 喷 涂 | F111 | Cr5 B1.5 Si3 Ni30 Fe Rem. | HB 150 | Spraying of bearing and cutting parts etc. |

F113 | Cr10 B1.5 Si3 Ni Rem. | HB 250 | Spray-fusing or spraying, such as roll, piston and axle of wear and corrosion resistance. | |

F313 | Cr15 B1.5 Fe Rem. | HB 250 | Spraying of dryer of papermaking and axle. | |

F314 | Cr18 Ni9 B1.5 Fe Rem. | HB 250 | Spraying of axle. | |

F412 | Sn10 P0.3 Cu Rem. | HB 80 | Spraying of axle and bearing. | |

F512 | 复合Al5Ni95 | Backing spray of transition layer between base and working layer. | ||

PTA hardfacing 等 离 子 弧 喷 焊 | F221 | Cr26 W5 B0.7 Co Rem. | HRc 43 | PTA hardfacing of sealing surface of high temperature and high pressure valve and the edge of hot shearing tool. |

F223 | Cr21 W5 B1.5 Co Rem. | HRc 40 | PTA hardfacing of parts resistance to wear and corrosion at high temperature, such as valve under high temperature and high pressure, and blower. | |

F321 | Cr13 B1.5 Si1 Fe Rem. | HRc 45 | PTA hardfacing of corrosion-resistant parts under mid-temperature and mid-pressure, such as stop-plate etc. | |

F322 | Cr23 Ni13 Si5 B1 Fe Rem. | HRc 40 | PTA hardfacing of corrosion-resistant parts under mid-temperature and mid-pressure, such as valve base etc. | |

F422 | Sn10 P0.3 Cu Rem. | HB 80 | PTA hardfacing of axle and bearing etc. |

-

13730556272

-

0319-5396239

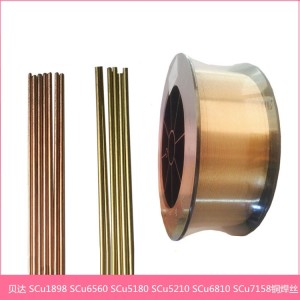

贝达 F203钴基粉 Co40钴基合金粉末 现货

¥ 258.00 ~ ¥ 260.00

¥258.00

5600千克可售

询价单发送成功~