- 产品

- 详情

- 推荐

收藏

¥面议

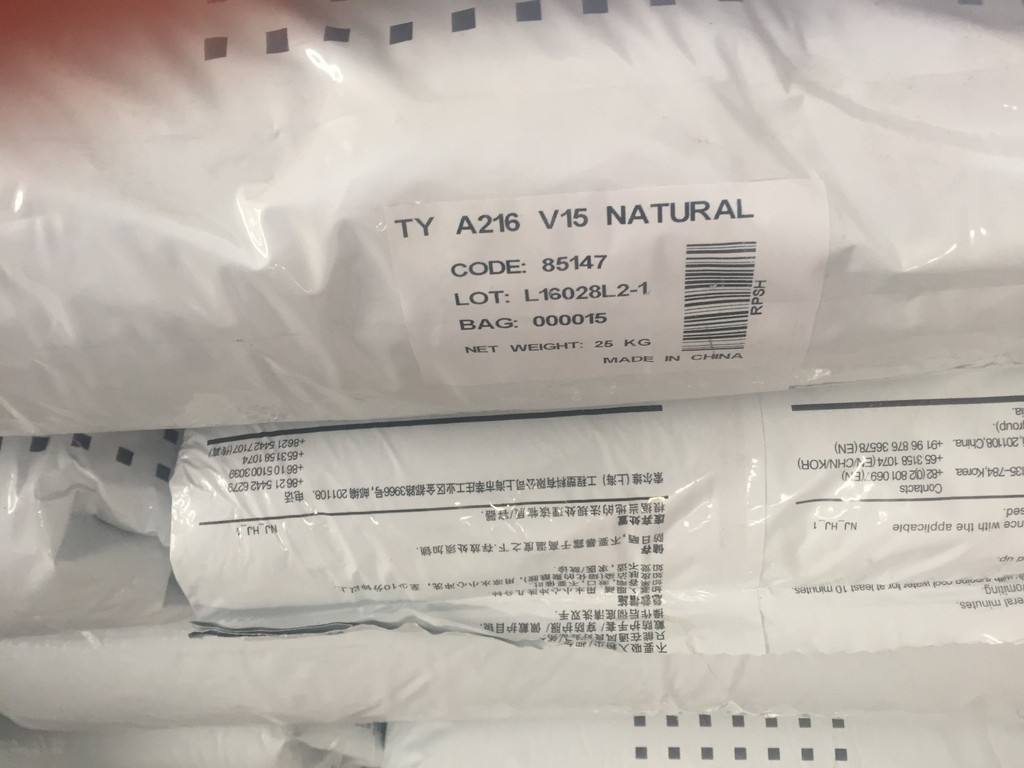

25千克起订

产品规格

可售数量: 10000千克

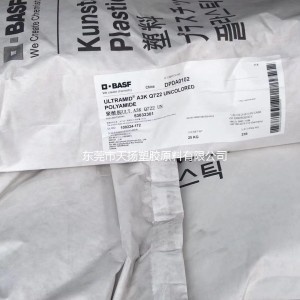

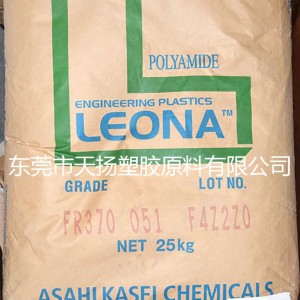

A216V15苏威(原罗地亚)玻纤增强PA66尼龙聚酰胺热性能和机械性能出色结合,A 216 V15,含15%玻纤增强,经润滑,出色的热性能和机械性能,可用于汽车工业,电器工具零部件,运输和建筑业等。原厂原包,提供原厂质量检验证书(COA),A216V15物性表等资料。

该产品装在气密袋中,可以立即使用。如果原始材料吸收了水分,则必须使用除湿的空气干燥设备将其干燥,-20°C。建议时间为2-4h。

注射建议:

对于增强聚酰胺,BASF建议使用碳含量高并经过抛光处理的高纯度钢,以避免或限制磨损。例如:X38CrMoV5-1(EN规范)-1.2367

/1.2343(DIN规范)或X160CrMoV12(EN规范)-1.2601

/1.2379(DIN规范)。在对表面质量有很高要求的情况下,可以考虑模具温度高达120°C。

建议采用诸如加工温度之类的加工参数,并可根据注塑机尺寸,零件几何形状/设计进行调整。

PA66 A216V15物性表:

| Physical | Dry | Conditioned | Unit | Test Method |

Density | 1.24 | -- | g/cm³ | ISO 1183 |

Water Absorption (23°C, 24 hr) | 1.1 | -- | % | ISO 62 |

| Mechanical | Dry | Conditioned | Unit | Test Method |

Tensile Modulus | 6200 | 4300 | MPa | ISO 527-2/1A |

Tensile Stress (Break) | 125 | 90.0 | MPa | ISO 527-2/1A |

Tensile Strain (Break) | 4.0 | 8.0 | % | ISO 527-2/1A |

Flexural Modulus | 5300 | 3500 | MPa | ISO 178 |

| Impact | Dry | Conditioned | Unit | Test Method |

Charpy Notched Impact Strength | 7.0 | 7.5 | kJ/m² | ISO 179/1eA |

Charpy Unnotched Impact Strength | 41 | 67 | kJ/m² | ISO 179/1eU |

Notched Izod Impact Strength | 6.0 | 9.0 | kJ/m² | ISO 180/1A |

| Thermal | Dry | Conditioned | Unit | Test Method |

Heat Deflection Temperature (1.8 MPa, Unannealed) | 245 | -- | °C | ISO 75-2/Af |

Melting Temperature (DSC) | 263 | -- | °C | ISO 3146 |

CLTE - Transverse (23 to 85°C) | 0.000035 | -- | cm/cm/°C | ISO 11359-2 |

| Electrical | Dry | Conditioned | Unit | Test Method |

Surface Resistivity | 6.0E+14 | 1.0E+12 | ohm | IEC 60093 |

Surface resistivity | -- | 1.0E+12 | ohm | IEC 60093 2 |

Volume Resistivity | 1.0E+15 | 1.0E+13 | ohm·cm | IEC 60093 |

Volume resistivity | 1.0E+13 | 1.0E+11 | ohm·m | IEC 60093 2 |

Electric Strength | 31 | 30 | kV/mm | IEC 60243-1 |

Electric strength | 31 | 30 | kV/mm | IEC 60243-1 2 |

Relative Permittivity (100 Hz) | 4.00 | 9.00 | IEC 60250 2 | |

Relative Permittivity (1 MHz) | 3.70 | 4.00 | IEC 60250 2 | |

Dissipation Factor | 0.010 | 0.11 | IEC 60250 | |

Dissipation Factor (100 Hz) | 0.010 | 0.15 | IEC 60250 2 | |

Dissipation Factor (1 MHz) | 0.010 | 0.11 | IEC 60250 2 | |

Comparative Tracking Index | IEC 60112 | |||

Solution A | 600 | 600 | V | |

Solution B | 525 | -- | V | |

Comparative tracking index | -- | 600 | IEC 60112 2 | |

| Flammability | Dry | Conditioned | Unit | Test Method |

Flame Rating (1.60 mm) | HB | -- | UL 94 | |

Glow Wire Flammability Index (1.60 mm) | 650 | -- | °C | IEC 60695-2-12 |

Oxygen Index | 24 | -- | % | ISO 4589-2 |

| Additional Information | ||||

Dry | The value listed as Melting Temperature (DSC), ISO 3146, was

tested in accordance with ISO 11357. | |||

| Processing Information | |||

| Injection | Dry | Unit | |

Drying Temperature | 80.0 | °C | |

Suggested Max Moisture | 0.20 | % | |

Rear Temperature | 260 to 270 | °C | |

Middle Temperature | 270 to 280 | °C | |

Front Temperature | 280 to 290 | °C | |

Mold Temperature | 60.0 to 80.0 | °C | |

A216V15苏威(原罗地亚)玻纤增强PA66尼龙聚酰胺热性能和机械性能出色结合

¥面议

¥面议

10000千克可售

询价单发送成功~